ECU Controllers

TTTech Auto TTC 500

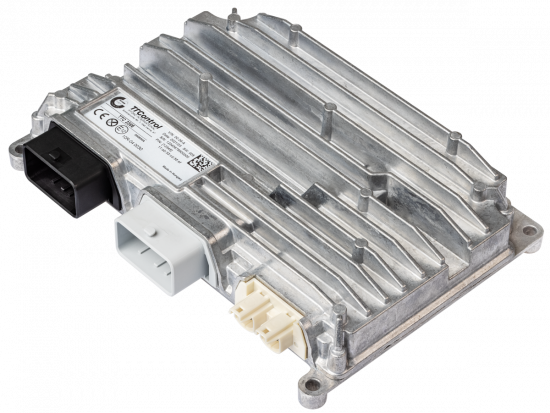

The TTC 500 family consists of high-end safety control units designed to satisfy upcoming needs for a wide range of high-end applications like construction and agricultural machines. These high-end controllers with a powerful dual-core ARM Cortex®-R4 lockstep processor are protected by a compact, automotive-style housing suited for harsh environments.

The extensive I/O set with various configuration options makes the TTC 500 control units suitable for a wide range of high-end applications: For example, a group of 8 I/O pins can be individually configured for use as voltage output, digital output or analog input. Another use case is to build up a centralized architecture using one of the TTC 500 safety controllers for the whole vehicle.

TTC 500 control units are available in five variants, TTC 508, TTC 510, TTC 540, TTC 580 and TTC 590, with different I/O sets and interfaces to meet the different requirements of the OEMs for a high-end controller.

TTC 500

- 96 I/Os with multiple configuration options

- Up to 7 CAN interfaces

- Configurable CAN termination

- Ethernet / BroadR-Reach®

- Automotive-style aluminium housingfor rough operating conditions

- Total current up to 60A

- SIL 2 (EN 61508) / PL d (EN ISO 13849) / AgPL d (ISO 25119)* / ASIL C (ISO

-

26262)* TÜV certified controllers

- Output shut-off in groups

- 32-bit 180 MHz dual-core lockstep

- Floating-Point-Unit

- Up to 2.3 MB RAM / 32 MB Flash

TTTech Auto TTC 2300

The TTC 2300 family is the first member of a complete and scalable series of controllers designed to meet the needs of upcoming highly automated and smart vehicles.

High processing power, high-speed connectivity and large memory make the robust electronic control units (ECU) the ideal choice for advanced electronic architectures and for future automation and assistance systems. The ECUs are designed for use in rugged operating environments and operate under harsh conditions and extreme temperatures.

Innovative features in smart vehicles are leading to an increase of the amount of data to be processed and stored. Therefore, the TTC 2300 family is equipped with large internal and external memory. Infineon’s latest high-performance CPU, the second-generation AurixTM TriCoreTM, provides the right computing power, ready for future vehicles.

Flexibility and connectivity for advanced vehicle functions and assistance systems are ensured by an extensive set of inputs and outputs (I/O) and various interfaces like CAN and Ethernet. The highly flexible I/Os make the controllers the perfect, cost-effective solution for a wide range of applications. The inputs can be configured for various sensor types and the outputs can be used to control hydraulic valves, electric motors, lamps or LEDs.

The ECU collects data from analog, digital and smart sensors and can communicate via 100Mbit/s Ethernet fast and efficiently with other components in the vehicle; for example, with a telematics gateway to upload the collected data to the cloud.

Electrification is a rapidly growing trend that will affect entire industries. The H-Bridge functionality, available in the TTC 2300 product family, efficiently controls various electric motors available for use in vehicles. This not only improves the precision of the vehicle, but also leads to an increasing number of electrified vehicle functions for higher sustainability.

TTC 2300

The TTC 2300 family helps introduce innovative, safety-related features, reduces the cost of vehicle testing and validation, and helps the manufacturers stay on the cutting edge of modern vehicle architectures.